Quality and quantity at AMB 2024 are convincing – CHIRON draws a positive conclusion

25th September 2024

Despite unstable economic and political conditions, the industry is sending positive signals from the AMB in Stuttgart. The trade fair company and individual exhibitor voices report a successful week: full occupancy of the halls with 1,244 exhibitors and a good 65,500 visitors from 78 countries provided a lot of discussion and networking. The Chiron Group also draws positive conclusions from the five days of the trade fair.

Revitalize important, strong and recognized values such as product quality, cost-effectiveness and innovative strength in order to stand out positively and thus survive in global competition. With this orientation, the Chiron team in Stuttgart presented its customers with manufacturing solutions and products in more than 500 individual discussions that provide machining companies with the right tools for the future.

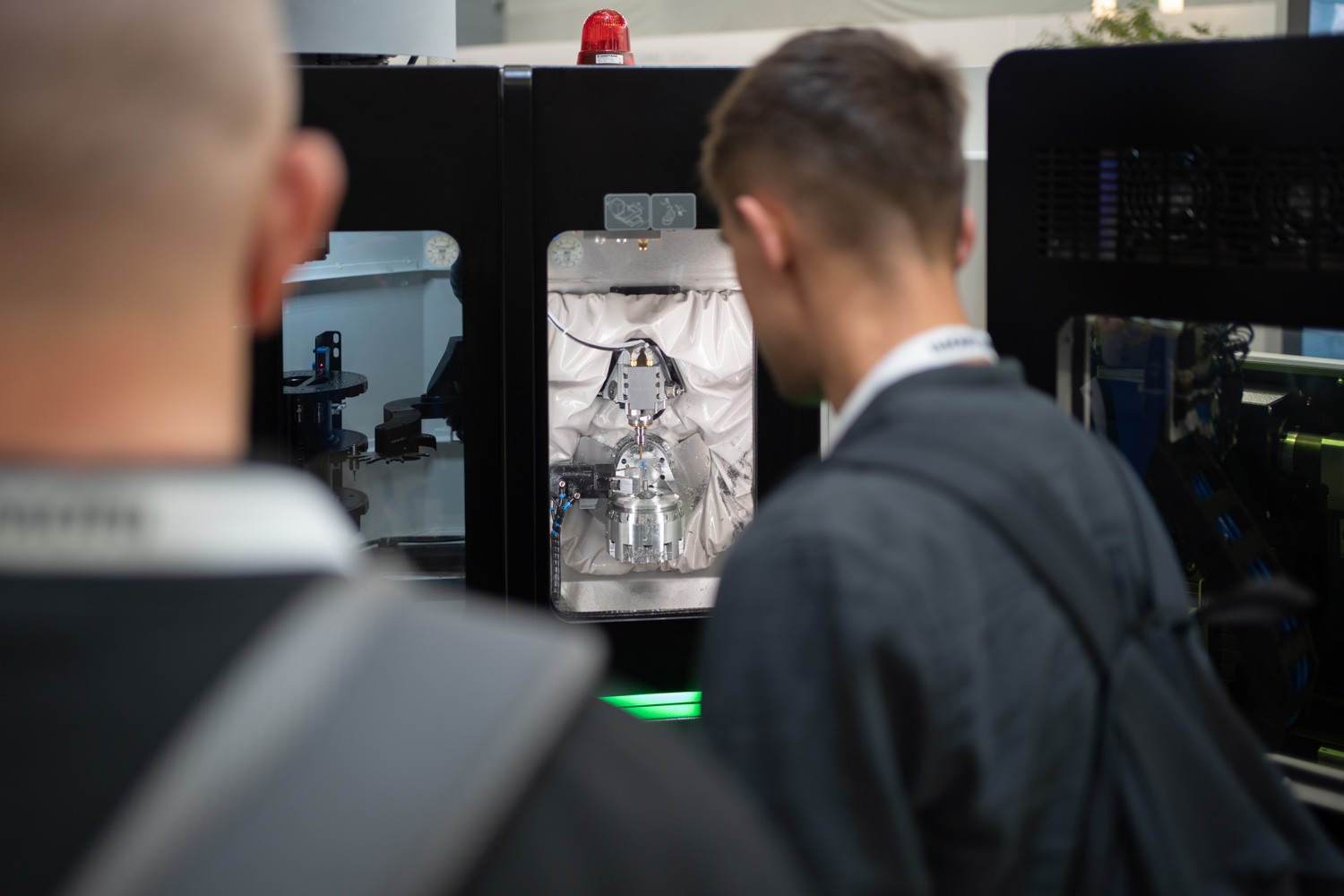

There was great interest in micro-machining with the Micro5, especially from medical technology and the watch and jewelry industry. Why should components of just a few centimeters be manufactured on machines that are essentially oversized in terms of space, mass and energy requirements? The Micro5, which is adapted to these “small and delicate” products, is highly precise and, at just 0.5 kW in just 1 m2, has clear advantages in terms of energy efficiency and footprint. It could be seen live in Stuttgart in combination with workpiece automation and an AGV (autonomous guided vehicle) - from prototypes to large series, a future-oriented manufacturing solution for everyone who "micro-machines" their parts.

The trend towards automating a manufacturing process is unbroken, which is also confirmed by the inquiries at AMB. Chiron's automation and application team, which has grown to over 40 employees in five years, has presented a diverse product range: integrated automation on MT centers, extensive standard automation from the Variocell range, highly autonomous isolated solutions and linked system solutions. In addition to the aforementioned automation solution for the Micro5, a standard Variocell Uno for series production on double spindle centers showed that the automation-machine interface in the Chiron Group is an integral part of the standard and turnkey business.

The highlight at the Chiron stand was the world premiere of the FZ19 S five axis. With the new Series 19, a vertical machining center is coming from Tuttlingen that is a good 25% faster when machining from solid material and complex workpieces. The optimal design of the work area in relation to the workpiece dimensions and the Chiron Group's own spindles ensure high-precision and particularly dynamic machining in aluminum, steel and cast iron. For manufacturing and production, the overall Series 19 package is intended to open up new perspectives for users to design their manufacturing solutions precisely, productively and reliably.

The news that all four gearing technologies have been integrated into the MT 715 series in collaboration with Paul Horn and Saacke also received a lot of attention - the topic fits perfectly with the times. Chiron recognized the trend in good time and users now have a safe alternative to specialized gear cutting machines to completely mill, turn and gear parts. By the way, 1 billion gears are manufactured worldwide every year.

“All in all, we can be very satisfied with the result of the trade fair appearance,” says Bernd Hilgarth, CSO of the Chiron Group. “It is too early to speak of a clear upswing,” continued Hilgarth, “even if the prospects are better than we dared to hope before the AMB. We will, the industry will know more towards the end of the year.”

About the CHIRON Group

The CHIRON Group, headquartered in Tuttlingen, Germany is a global company specializing in CNC vertical milling and mill-turn machining centers, as well as turnkey and automation solutions. Comprehensive services and digital solutions complete the portfolio. The Group has a global presence, with production and development sites, sales and service subsidiaries, and sales agencies worldwide. Around two thirds of machines and solutions that are sold are exported. Key customer sectors are the automotive, mechanical engineering, medicine and precision engineering, aerospace industries, as well as tool manufacturing.

Contact person for editors:

Peter Wustrow GmbH Werbeagentur

Geschäftsführung

Peter Wustrow

Heumadener Str. 15

73760 Ostfildern

M +49 171 2766238